Risk-Based Inspection of Moorings: BE&R Consulting’s Approach to OPEX Efficiency

Over the last decade BE&R have developed and proven through implementation a light weight and easy to maintain Risk-Based Inspection (RBI) tool for FPSO mooring systems. The result is a tool set that:.

- Uses a risk-based approach to implement an inspection plan that is tailored to the specific condition, service environment, and operating life of the mooring system, potentially leading to considerable savings in operational expenditure (OPEX) and avoid component failure in operation.

- Allows optimisation over various RBI updates and Class reviews

- Is simple to implement and handover to operations

- Is designed to interface with output from digital twins and as required analysis

- Is designed to integrate into:

- Inspection and repair planning

- Work packs for inspection (cut and paste modules)

- Emergency Response Plan

- Emergency Repair Response Plans

- Can be applied to other floating facilities such as CALM buoys, MOPUs and floating wind, encompassing any offshore moored assets.

The RBI Process and Methodology:

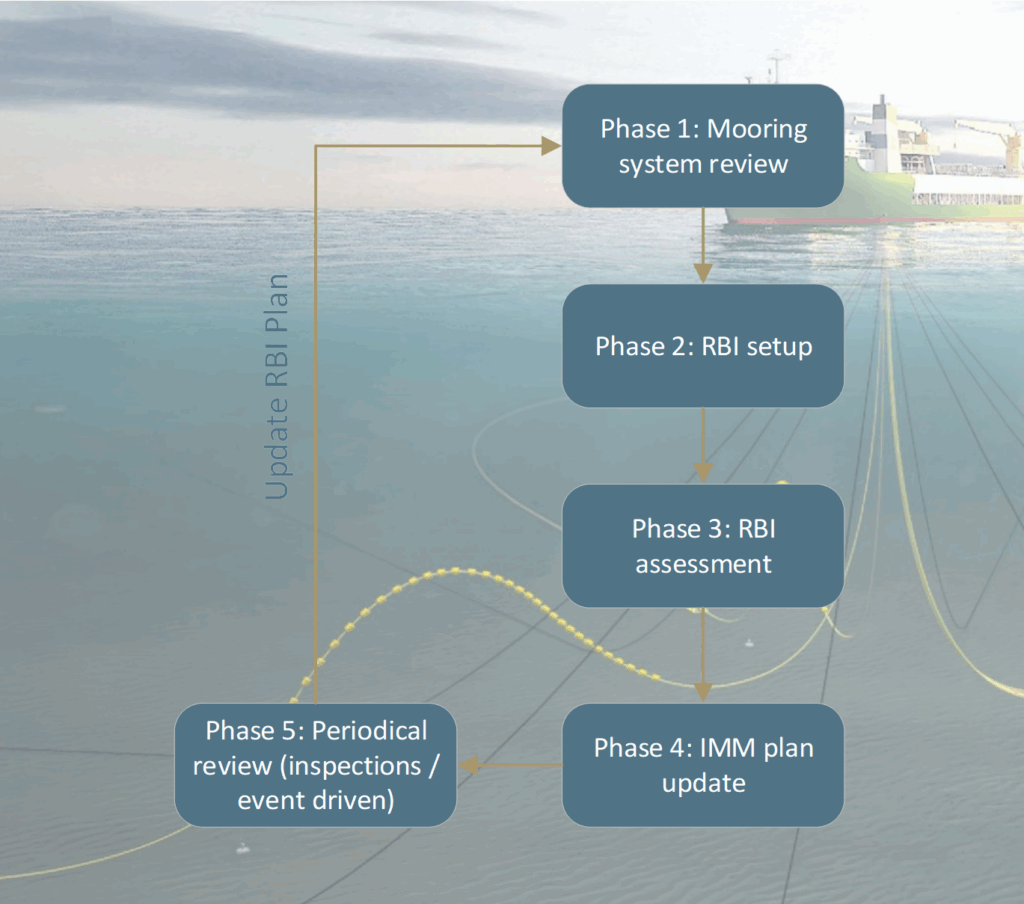

The RBI process, as applied to an FPSO mooring system, follows a structured five-phase approach in line with API-RP-580/581:

- Phase 1: Mooring System Review: This initial stage involves gathering and reviewing all relevant information, including design documents, historical inspection data, and industry updates. The goal is to establish a comprehensive understanding of the mooring system and identify potential limitations and inspection acceptance criteria.

- Phase 2: RBI Setup: Here, credible threats to each component of the mooring system are identified and reviewed. Semi-quantitative risk matrices are established and calibrated based on these threats and experience from similar RBI assessments. The risk matrix maybe further calibrated as an outcome of periodical reviews .

- Phase 3: RBI Assessment: This core phase involves assessing each part of the mooring system against the identified threats to determine the associated risk. This includes evaluating the consequence of failure, based on the Clients operational risk matrix, financial implications, and the likelihood of failure, which takes into account the specific threats to the mooring system’s operating performance. The unmitigated risk is then determined, and appropriate IMM activities are assigned to reduce this risk.

- Phase 4: IMM Plan Update: The outcomes of the RBI assessment are used to update inspection criteria and the overall Inspection Maintenance Monitoring (IMM) plan. This also involves developing or updating Inspection Scope Sheets and engaging with Class for approval.

- Phase 5: Periodical Review: The RBI assessment is recognised as a continuous improvement process. Regular reviews are performed, triggered by new inspection data, changes in operating conditions, or incidents. These reviews ensure the RBI plan remains current and effective. Review workshops, involving key stakeholders such as the Operator, Class, and regulator are crucial for aligning on the RBI setup, assessment, and findings.

BE&R Consulting’s Approach:

BE&R Consulting’s involvement in multiple Australian and SEA Mooring System RBI’s demonstrates an expertise in applying risk-based principles to complex offshore assets. Our approach, is characterised by:

- A systematic and structured methodology: Following the defined five-phase RBI process ensures a thorough and auditable assessment.

- Data-driven decision making: The RBI process heavily relies on gathering and analysing historical inspection data and design information to inform the risk assessment.

- Collaboration with stakeholders: The emphasis on review and alignment workshops highlights a collaborative approach with Operator, class and regulator. This ensures that the RBI plan is technically sound and aligned with operational needs and regulatory requirements.

- Focus on credible threats: The RBI process specifically focuses on identifying and evaluating threats relevant to the mooring system, such as corrosion, wear, fatigue, and mechanical damage.

- Semi-quantitative risk assessment: The use of semi-quantitative ranges for likelihood and consequence of failure provides a structured way to evaluate risk while acknowledging the inherent uncertainties. During periodical reviews these ranges maybe calibrated based on findings.

- Integration with existing frameworks: The RBI methodology is aligned and integrated with the Client’s operational risk matrix and Structural Integrity Management Procedure.

Potential for OPEX Cost Savings:

The adoption of an RBI strategy for an FPSO mooring system holds significant potential for OPEX cost savings by:

- Optimising inspection frequencies: Instead of adhering to fixed time intervals, inspection frequencies are determined by the level of risk associated with each component and potential threat. This allows for less frequent inspections of low-risk areas and more focused attention on critical components.

- Tailoring inspection methods: The RBI can inform the selection of the most appropriate inspection methods for specific threats and components. This ensures that inspection efforts are effective and cost-efficient.

- Reducing unnecessary interventions: By focusing inspections on areas of higher risk, the RBI approach can help avoid unnecessary maintenance or replacement activities on components that are still in good condition.

- Improved planning and resource allocation: A clear understanding of the risks and associated inspection requirements allows for better planning of inspection campaigns and allocation of resources.

- Extending asset life safely: By proactively managing risks and intervening only when necessary, an integrated RBI system can contribute to safely extending the operational life of the mooring system, deferring potentially large capital expenditures for replacements.

BE&R’s integrated proactive approach

BE&R recommend an integrated proactive approach to developing a robust and structured RBI System to managing the integrity of critical infrastructure. By focusing inspection efforts based on a thorough assessment of risk, this methodology offers a clear pathway to achieving significant OPEX cost savings while ensuring the continued safe and reliable operation of a Client’s FPSO. The iterative nature of the RBI process, with its emphasis on regular reviews and updates based on new data, further enhances its potential to deliver long-term cost efficiencies.